You are here ![]() Home

Home ![]() Parts Mall

Parts Mall ![]() Elevator Mall

Elevator Mall ![]() Residential Parts

Residential Parts

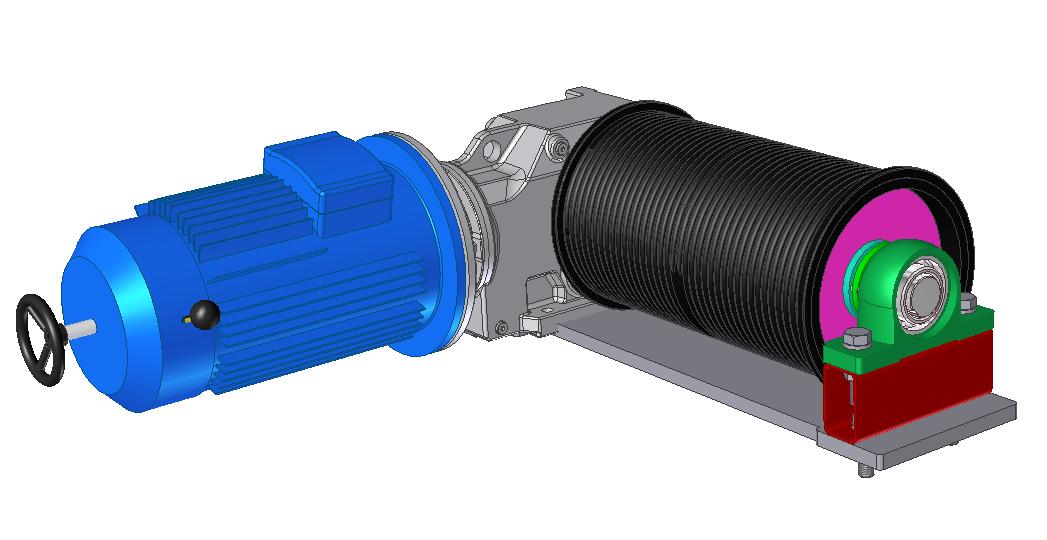

DOUBLE WRAPPING DRUM MACHINE

Overhead Drum Machine, KS-DH950-L•Double Wrapping drums can be used to maximize the efficiency of the hoistway space by use two ropes hoisting in a drum. 2 ways wrapping is much simpler than single wrapping, so it is convenient to install even in a narrow hoistway space. •The machine weighs about 260lbs. Make sure you have adequate rigging for hoisting the machine and machine base. One method of getting the machine and base in place is to put them on a hand operated lift truck (such as McMaster Carr 37T22), and use the car frame (sling) as a working platform. Hoist the car frame (sling) up to the top of the rails, and use the lift truck to raise the machine and base into position. |

| Model | Rated Voltag (VAC)/3 PH. | Car Speed (FPM/MPS) | Rated Load (Lbs/kgs) | Gear Ratio | Drum Diameter (mm) | Output Power (K/HP) | Drawing |

| DW 100# | 220/380 | 40/12 | 100/45kg | 80 | 130(5.12") | 0.25(3/4HP) | DW 100# |

| DW 300# | 220/380 | 40/12 | 300/136kg | 100 | 150(5.93") | 1.5(2HP) | DW 300# |

| DW 500# | 220/380 | 40/12 | 500/230kg | 100 | 215(8.48") | 2.2(5PH) | DW 500# |

Installation | |

1. Install the machine bed and machine (drum motor) to the top of the rail stack, See right figure. 2. Thread one end of the cable through the hole in the drum. Install a wire rope clamp (also known as a Crosby clamp) on the end of the cable. Wrap the cable around the drum until the cable is about even with the lowest landing. You may need to secure the cable with tape or wire to keep it in the grooves of the drum until it is connected to the car and has weight on it. Repeat on the other side. Be sure to clean out the holes from debris and dust before inserting the anchors. 3. Once the cables have been attached and properly secured to the drum machine, the live end (end of cables to be connected to car frame/sling) must be secured to the wedge sockets. 4. At this point, the car frame may be lowered. 5. Rope Winding direction pass round the drum, down to hitch point of hoisting, close to side of the wall of hoistway at the center line of guide rail, not to part of car cage, or the car frame. Wire running way should be detached from any part of machine bed and bed plates in downward and upward of lift movement. |  |

Download to see all components If More Inquiries?Ask here to find the product that meets your needs |